Dear Quality Butter Lovers and Kriemhild Supporters, |

| Today cultured products are made a bit differently. Since regulated pasteurization destroys all bacteria in milk, micro-bacterial cultures must be added to cream to begin a controlled fermentation. This is how our Crème Fraîche is made, and it is also the first step to making our new Cultured Butter. Once the cream and culture has sat at the correct temperature for an amount of time, it is churned slowly in small batches to reduce moisture and increase butterfat percentage. Once the cream and culture has sat at the correct temperature for a specific amount of time, it is churned slowly in small batches to reduce moisture and increase butterfat percentage. By law, American butter must contain at least 80% butterfat. However, like with our other butters, our Meadow Butter and our Bakers’ Butter, we set the bar a bit higher and shoot for what is called “European Style” butter. Our Cultured Butter currently has a butterfat percentage of 84%. The higher butterfat content intensifies the natural flavor of all our butters. |

Culturing cream before churning it into butter enhances the natural sweetness of the cream while also bringing out a subtle, nutty, tang. Like yogurt and Crème Fraîche, the probiotics in Cultured Butter aid in digestion. Culturing also increases the acidity of the butter, which helps to tenderize dough, resulting in tender crumbs and crusts.

| You can use Cultured Butter for all the same things you’d use any of our butter for: baking, cooking, spreading, eating from a spoon. It’s made with the same care and attention as our Meadow Butter and Bakers’ Butter. It just tastes a bit different. You can find our new Organic Cultured Butter at the Kriemhild Kupboard, our Online Store, or at your closest Meadow Butter or Bakers’ Butter retailer. Already a big fan? Grab yourself some Cultured Butter Merch. |

| While we have been participating in farmers’ markets here in CNY for years, now, it may be a little known fact that a majority of our butter is actually loaded on pallets and shipped out to stores throughout the northeast. It’s not an easy feat, managing logistics with supply and demand, but the challenge is one that we embrace as part of our mission to bring quality crafted, locally produced food to you. When you’re just getting started as a young business...where do you start? We were lucky in Upstate New York to have a distributor in our “neighborhood” that was at the forefront of the local food movement; a pioneer who knew the value in connecting local producers to consumers: Regional Access |

Just as we were adding the word distribution to our vocabulary in 2011, the ownership at Regional Access was being passed along to the next generation and a couple of long time, dedicated individuals. Like any small business, we see the owners often in our business to business interactions. It’s not unusual to see Dana Stafford, President and GM, behind the wheel of their neatly painted Regional Access tractor trailer picking up those pallets we mentioned before.

If you’re buying our butter at Union Market, your local health food store or co-op, there’s a good chance that that package was delivered by Regional Access. They distribute to stores and restaurants all over New York State and New Jersey. They go above and beyond for their customers, truly. I’ve seen multiple videos of their drivers braving stormy weather in the steep hills of Ithaca.

If you’re buying our butter at Union Market, your local health food store or co-op, there’s a good chance that that package was delivered by Regional Access. They distribute to stores and restaurants all over New York State and New Jersey. They go above and beyond for their customers, truly. I’ve seen multiple videos of their drivers braving stormy weather in the steep hills of Ithaca.

In addition to Regional Access and Dairy Wagon, we work with several other distributors that deliver our Meadow Butter to stores, restaurants and bakeries to the Metro New York region and a bit into Boston. Each covers a particular or type of customer, like Whole Foods, food-service-only accounts, or even direct home delivery. These distributors are small businesses like ours, playing an incredibly vital role in building a human and community based, quality food system.

DIY DeliveryOur small company is made up of a staff of four with two working owners. We’re a young 8 years old in the business, and by working with co-packers, we are able to accomplish quite a bit with a small team. Being able to connect with and utilize these distributors allow our business to thrive. Shipping frozen food throughout the region is expensive and it costs more than just gas and time when you also consider the environmental impact, which we do. As such, we still have to coordinate getting the finished goods from the creamery out to those large customers. We have two cold storage options, one at our office in Hamilton and at Food Features in Syracuse. It takes about a full day to get an order ready for a Metro New York run where we deliver to 3 distributors and 3 large wholesale accounts, one of those being Fresh Direct. |

In preparation, we drive our leased truck (thank you, DeCarolis) from Hamilton to Food Features in Syracuse, just off the Thruway and pick up a pallet or two of stored product. We head back to homebase and finish loading the truck by hand as loading docks and electric pallet jacks are luxury items out of our reach. Honestly, we’re happy when the walk in freezer isn't blowing snow inside. We also write all of our orders by hand on good old fashioned carbon copy paper so we can track where our cases of Meadow Butter are going.

| The Metro New York delivery run is a 2-person job, and sometimes a two day run. Being regulated by Department of Transportation means our drivers can only be on the road for 14 hours and driving for 11. (Remember that small staff of 6 people mentioned earlier? Three of us are also “drivers”) Driving down to New York City and back uses up most of the allowable drive time. Once down there, we have to navigate traffic jams, spotty GPS systems, trucks only and no trucks allowed lanes, etc. Then we have to consider our customers- some have limited storage space and others have tight receiving hours or long wait lines. |

Every day we’re considering how best to get our product to those who want it. A significant amount of time and thought go into organizing our distribution. With that said, we deliver to only a handful of distributors. Those folks, however, are delivering to hundreds of customers on a weekly basis. Our distributors are good at what they do. They’ve invested in delivery system software that not only incorporate routes designed for trucks of a specific weight and height, but also incorporate back-hauling, cross docking and freighting for other distributors and large accounts. They’re doing their best to maximize their haul and starting their trucks at 2 and 4am when the roads are clear so there’s less traffic that cause their trucks to idle.

Not only do distributors play a vital role in our business getting product from A to the rest of the alphabet, but they also are often the face of our company. The first impression customers have of our glorious butter and crème fraîche is served by their sales teams. They provide a bridge of communication between us and our customer.

In fact, that 1lb roll you love so much can be attributed to our distributor, Solex Fine Foods. After receiving feedback from their customer restaurant, Daniel, we started working on producing rolled butter. The chefs were looking for a specific diameter roll to cut into medallions. One happy accident later, we made 2,000 lbs of rolled butter in the wrong diameter. Turns out, the chefs weren’t the only ones who preferred rolled butter wrapped in white paper.

At a casual event just last week, I saw the owner of Solex, Markus Draxler sampling products, just as I was. Here we both were, on a Wednesday evening after already putting in a full days work, engaging our customers and showing appreciation for their patronage. A few months ago, while I didn’t know it at the time, I watched the former owner of Solex and still a good friend of Markus’ unload a pallet from our truck. I learned later that he started the business by selling langoustines from his homeland in Scotland to high end restaurants in Manhattan.

“It’s not personal, it’s just business” is not a phrase that resonates with us here at Kriemhild. We believe all relationships are personal, including business relationships. We work with the same distributors that we started with in 2012 and 2013. We value their work and respect them as individuals. We’ve gotten to know them, and grow with them and ultimately, like you, they help us do a better job.

Not only do distributors play a vital role in our business getting product from A to the rest of the alphabet, but they also are often the face of our company. The first impression customers have of our glorious butter and crème fraîche is served by their sales teams. They provide a bridge of communication between us and our customer.

In fact, that 1lb roll you love so much can be attributed to our distributor, Solex Fine Foods. After receiving feedback from their customer restaurant, Daniel, we started working on producing rolled butter. The chefs were looking for a specific diameter roll to cut into medallions. One happy accident later, we made 2,000 lbs of rolled butter in the wrong diameter. Turns out, the chefs weren’t the only ones who preferred rolled butter wrapped in white paper.

At a casual event just last week, I saw the owner of Solex, Markus Draxler sampling products, just as I was. Here we both were, on a Wednesday evening after already putting in a full days work, engaging our customers and showing appreciation for their patronage. A few months ago, while I didn’t know it at the time, I watched the former owner of Solex and still a good friend of Markus’ unload a pallet from our truck. I learned later that he started the business by selling langoustines from his homeland in Scotland to high end restaurants in Manhattan.

“It’s not personal, it’s just business” is not a phrase that resonates with us here at Kriemhild. We believe all relationships are personal, including business relationships. We work with the same distributors that we started with in 2012 and 2013. We value their work and respect them as individuals. We’ve gotten to know them, and grow with them and ultimately, like you, they help us do a better job.

Hugs and Butter,

Lindsey, Kriemhild Co-Owner

P.S. Stay tuned for next week’s short reel silent film--it’s a tribute to our main mode of distribution before we started leasing a truck...

Lindsey, Kriemhild Co-Owner

P.S. Stay tuned for next week’s short reel silent film--it’s a tribute to our main mode of distribution before we started leasing a truck...

Ingredients:

- 450g pumpkin flesh

- 150-180ml milk

- 270g rice flour

- 225g soft Meadow Butter

- 220g sugar

- 4-5 eggs (depends on the size)

- 2.5 tsp organic baking powder

- 2-3 tsp cinnamon

- 1 pinch ground nutmeg

- 1 pinch ground ginger

- 1 tsp vanilla extract

- 1 pinch salt

- 6 pears, firm and not ripe

- a bit powdered sugar

- springform pan 11-12 inches

Method

Pre-heat oven to 360 degrees F. Mix milk and pumpkin flesh to make puree. Prepare dough by beating the soft butter together with the cane sugar, vanilla and salt for 5 minutes, then beat in the eggs one by one – each for 20-30 seconds. Beat in the pumpkin puree. Blend the rice flour, baking powder, cinnamon, ginger and nutmeg and stir into the batter by hand using a whisk or the dough hook of your hand mixer. Fill the batter into the springform pan, place the pears (wash and pat dry them before) into the batter and bake for 60-65 minutes (cover the cake for the last 20 minutes with foil – and make the toothpick test in the end to check, if the cake is done). Let the cake cool down on a cooling rack for 1 hour before serving. Dust with powdered sugar.

adapted from ourfoodstories.com

adapted from ourfoodstories.com

Tzatziki:

Falafel:

- 1 cup of crème fraîche

- Pinch of salt

- 1 tsp finely chopped garlic

- 1 tsp olive oil

- ½ of one large cucumber

Falafel:

- 2 tins chickpeas

- ½ red onion, chopped

- 2 tsp garlic

- 1 tsp cumin

- 2-3 small dried chillies

- 2 tbs chopped fresh coriander

- 2 tbs olive oil

- 3 tbs flour

For the FALAFEL:

Preheat oven to 180 degrees and grease two mini-muffin trays. Mix all ingredients except the flour, and either blitz in a food processor or mash by hand.Mix in the flour, adding extra if it’s too sticky. Roll the mixture into ping pong sized balls between your palms. There’s definitely a knack to this, so don’t worry if you start with a few weirdly-shaped ones. Put them into your muffin tins: if you have too many leftover, it’s fine to cook some on a baking tray Bake for about 40 mins, turning half-way through.

For the TZATZIKI:

Finely chop the cucumber: if you have time, it’s best to gather it in a clean tea-towel and squeeze out some liquid for a few minutes. Mix all the ingredients and keep it cool.

Preheat oven to 180 degrees and grease two mini-muffin trays. Mix all ingredients except the flour, and either blitz in a food processor or mash by hand.Mix in the flour, adding extra if it’s too sticky. Roll the mixture into ping pong sized balls between your palms. There’s definitely a knack to this, so don’t worry if you start with a few weirdly-shaped ones. Put them into your muffin tins: if you have too many leftover, it’s fine to cook some on a baking tray Bake for about 40 mins, turning half-way through.

For the TZATZIKI:

Finely chop the cucumber: if you have time, it’s best to gather it in a clean tea-towel and squeeze out some liquid for a few minutes. Mix all the ingredients and keep it cool.

As the Butter Churns

|

|

Author: Ellen Fagan and Victoria Peila

Categories

All

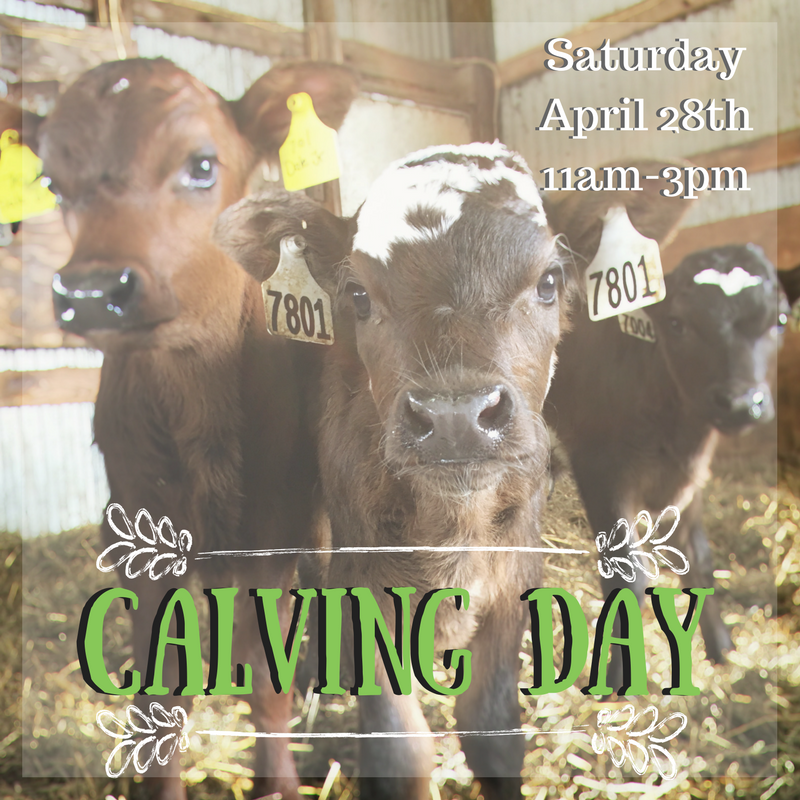

Calving

Camp Fiver

Carbon Sequestration

Certification

Community

Cows

#cremefast

Crème Fraîche

Environment

Farm Store

Grass

Grazing

History

Honor System

How It's Made

Kriemhild Kupboard

Labeling

Meadow Butter

Nutrition

Recipes

Red Gate Farm

Science

Seasonal

Soil

Values

Archives

November 2019

April 2019

March 2019

February 2019

March 2018

February 2018

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

RSS Feed

RSS Feed