|

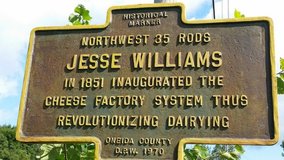

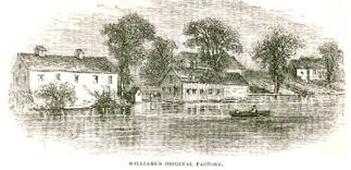

On July 8th, we will be attending and vending at the 3rd annual Little Falls Cheese Festival in Little Falls, NY. We have been diligent participants of the festival since its debut in 2015, but we still have yet to sample all the cheeses the event has to offer. In addition to a wide regional selection of artisan and farmstead cheese, the festival also features all things cheese-complementary, including, but not limited to: gourmet chocolates, artisan breads, pastries, spreads, and, of course, butter. As much as we love the abundance of artisan foods, live music, and good company that we experience throughout the day, what touches us the most is what the festival celebrates: the rich history of pioneer creameries and dairy food manufacturing in New York State. Herkimer Cheese Although Wisconsin and California are currently fighting for the title of largest cheese manufacturer in the United States, throughout the 19th century New York was the leading state in amount of creameries, with Little Falls, in Herkimer County, NY as its cheese capital. Due to the fame of Herkimer County Cheese, the first United States cheese exchange was hosted in Little Falls in 1850s, set the price of cheese for the country, and even influenced the cheese prices in Europe.  Multiple factors allowed Herkimer County to rise up as the cheese center of the United States. New York’s climate, which is ideal for grazing dairy cattle and making cheese and butter, and Jesse Williams who pioneered the “cheese factory” system. Before the cheese factory, cheese and butter making was essentially the work of farm wives and dairy maids. While the task was arduous and at times resulted in inconsistent cheese quality, skilled dairy maids could provide for their families with their craft. The first cheese factory in America was established in Rome, NY in 1851 after Jesse Williams, dairy farmer and cheesemaker, began processing milk delivered from his son’s dairy farm alongside his own to make cheese. Although milk cooperatives are common today, in the 1800s, this practice was novel. Jesse went on to accept more deliveries from other farms in the area and institute an efficient system of milk collection as well as consistent quality cheesemaking. The switch from farmhouse to factory cheesemaking empowered dairy farmers and manufacturers to produce over 49,000,000 pounds of cheese in 1850, compared to Wisconsin’s mere 400,000 pounds. In 1899 at least 1,611 factories in NY made either cheese or butter, 207 of which made both. Goshen Butter About 170 miles south of Little Falls, New York butter was having its heyday as well. In 1856, the first factory in the world specifically built to manufacture butter was built in Campbell Hall, Orange County, NY. Being constructed in the pre-refrigeration era, the creamery’s placement relied on the existence of a natural cold spring with which the butter was chilled. As with New York cheese, it was skilled farm wives and dairy maids who made butter popular in Orange County. These farmstead producers were already the main suppliers of butter to New York City which were delivered regularly by way of horses and carts. The butter of Orange County was famously known around the country as “Goshen Butter”. However, the ability to produce large quantities of butter of consistently high quality left the Campbell Hall butter factory responsible for New York State’s peak in butter production from 1860 to 1890. Ultimately, New York’s Herkimer Cheese and Goshen Butter faced the same sad fate. As refrigerated transport made it possible to ship fresh milk to New York City and other urban areas, the need for shelf stable dairy products sharply declined. Between 1890 and 1910, the production of New York butter decreased 80%. New York's Dairy Comeback

As much as the Little Falls Cheese Festival observes New York’s rich cheese production history, it is also a celebration of the revival of the state’s artisanal dairy crafters and small dairy industry. Although no longer the top producer of cheese and butter, dairy farming is still the leading agricultural industry in New York state. Entrepreneurs are taking advantage of New York’s abundance of quality milk and getting creative with it. Increasingly, farmers are bottling, branding, and marketing their own milk, small businesses are opening small batch creameries and making value-added products, and processors are collecting local milk from small dairies and using it to co-pack for national brands. As of now, New York State is the lead in yogurt production in the nation and its dairy manufacturing industry employees over 8,000 workers. In addition to feeding the economy, New York small dairy processors and dairy artisans are telling their farmers’ stories (if they’re not the farmer themselves) and responding to a growing consumer base that expects transparency, environmental stewardship, and quality by striving to create food that reflects those values. This is our mission at Kriemhild and we have joined many other fellow dairy processors that follow similar paths. It is true, the landscape of New York’s dairy industry has changed. But, as long as there are dairy farmers, there will be processors, and New York’s dairy will be rich. Sources: Sernett, Dr. Milton C. Say Cheese!: The Story of the Era when New York State Cheese was King. Cazenovia: Milton C. Sernett, 2011. "Governor Cuomo Announces New York State is Now Top Yogurt Producer in The Nation, Delivers on Key Promises Made at Yogurt Summit to Help Dairy Farmers." The Official Website of New York State. 18 April 2013. www.governor.ny.gov.

3 Comments

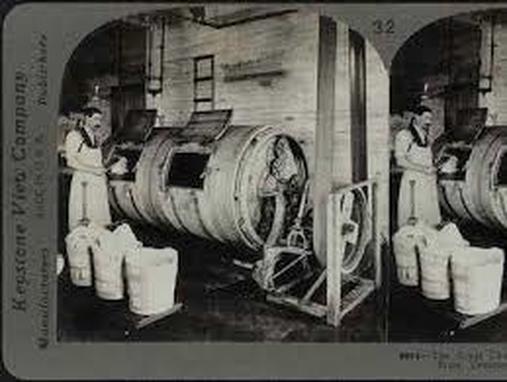

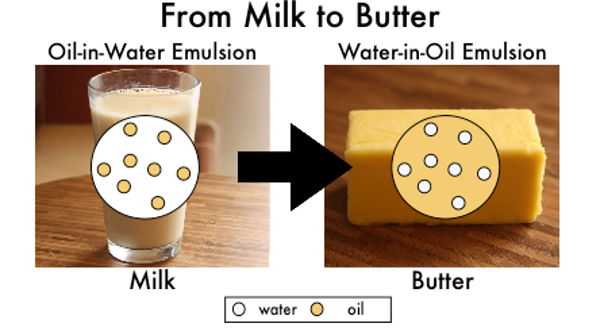

This June, we are inviting you, our customers, to join us in celebrating National Dairy Month - an annual tradition that acknowledges the contributions of the dairy industry to our health, our communities, and our environment. Originally created as National Milk Month in 1937 for the purpose of promoting the sale of milk, the National Dairy Council changed the name as the public embraced the opportunity to recognize the significant role that all dairy farmers and processors play in the food system. As a dairy processing business, we would like to celebrate National Dairy Month by highlighting the...well...process of turning local milk into your favorite Meadow Butter and Crème Fraîche. This week we will be shedding light on the details of our Meadow Butter production. Why Butter? When Kriemhild Dairy Farms was established in 2010, we were already committed to the advancement of grazing dairies and the creation of high-quality, grass-grazed dairy food. The flavor and nutritional benefits of grass-grazed dairy products manifest the the best in high-fat products. Therefore, when Kriemhild was developing its first product, butter was a natural choice, and ultimately became our signature creation. Our Co-Packer However, as a start-up agribusiness, we would not have been able to create our Meadow Butter without the unique partnership we have with our co-packer, Queensboro Farm Products in Canastota, NY. At the time of our founding, the farmers who founded Kriemhild -- including co-owners Bruce and Nancy Rivington, owners of Red Gate Farm -- were already shipping their milk to Queensboro. They were aware that Queensboro had a reputation for making butter with a higher than average butterfat, so it was a perfect place to begin our butter production. A typical relationship with a co-packer implies the employees of the facility handle all of the production and packing of a product for an external company. Our relationship with Queensboro, is atypical in that we, as a company, physically take part in the production and packing of our butter within the facility using a combination of both our own and Queensboro’s equipment. Making Dreams Out of Cream Red Gate Farm’s grass-fed milk is picked up and delivered by a trucking service and sold to Queensboro Farm Products every other day. The cream is separated from milk using centrifugal cream separator. This process, which takes about 24 hours naturally, only takes about 13 minutes. The remaining skim milk is sold on the general milk market or used to make other Queensboro products. The cream, which is approximately 38% fat, is pasteurized and transferred to a vat to temper. During the tempering process, between 18 and 24 hours, the fat globule restructures itself and continues to release latent heat. Once the cream has tempered, it’s then piped into a barrel churn. 42,500 pounds of Red Gate Farm’s milk will yield approximately 2,000 pounds of butter, however, this number will vary depending of the percentage of butterfat in the milk. The churn is a mechanical barrel that will spin about the speed of a clothes drying machine, tumbling the cream. The agitation of the cream disturbs the hydrophobic phospholipid membranes surrounding the milkfat globules. As Dr. Robert Bradley likes to describe it in his book, ‘Better Butter’: "Cream is an oil-in-water emulsion that turns into butter when inverted to a water-in-oil emulsion." After about 45 minutes of churning, small clumps start to form, a state known as “popcorn butter” or “butter grains”. At this point the whey is drained, the butter rinsed, drained again and the butter is sold and turned over to Kriemhild. As a team, we don hair nets, plastic aprons, clean rubber boots, and disposable gloves to prepare for a day of packing butter. We begin by doing a complete wash of all our equipment. If we are making salted butter, salt is added to the “popcorn butter” and then it is put through about another five minutes of churning. The fat globules that form the small clumps continue to fuse to each other, pushing our air and moisture, to a point where it is a single creamy, firm mass of butter. We use a mix of technology and elbow grease to pack our butter into different sized containers. All the butter is taken from the churn and placed in a low sheer pump with two strong metal augers that push the butter through a round pipe, similar to a play-doh factory toy. As the butter comes from the pipe it is cut to a certain size, placed on wax paper, and hand rolled to create our traditional rolls. Our two pound, five pound, and 50 pound sizes are also all hand packed. The only size not hand-packed is our 8oz container. To fill our half-pounders, our butter pump is connected to a rotary filler which directly fills our screen printed tubs to an accurate weight, places and heat seals a piece of foil to the top, and presses a lid to close it. When all the butter is packed in containers, it’s then put into labeled boxes for either direct delivery to one of our wholesale accounts or for storage until later. Then, the whole production room and equipment need to be rinsed, washed, and sanitized again. Depending on the size of the batch of butter, and the sizes of units we are packing, a day of butter production can last from 4 to 8 hours. This does not include the time it takes to load the pallets of boxes onto our refrigerated truck, travel back to our headquarters, and then unload and organize our inventory. Food production is also physically intense. It involves standing on hard ground for long hours, tedious periods or repetitive motions, lifting and moving heavy boxes, and no matter how hard we try to not get wet, we always get wet during washing. From Our Hands to Yours Food processing is hard work, but we love to be able to see the creation of our butter from pasture through to market. And although our reach is far, and growing, when you meet one of our team, whether they're delivering your order or at the farmer’s market, you can know that team member handing you your butter is the same person who has taken part in making it. Memorial Day has arrived, and summer is on its heels.As we welcome the season’s extra daylight and warmer weather, we remember that summer has different meanings for everyone. To Kriemhild it may be all about farmer’s markets and butter making, yet for many youngsters we know that summer means summer camp. There’s one summer camp in particular that we keep in mind all summer, and if you frequent to our self-service farm store, the Kriemhild Kupboard, you might know which one we’re always thinking of. As a triple-bottom-line company that equally values profits, planet, and people, we are always searching for ways to continue giving back into the communities that support us. To this end, 10% of the Kupboard’s profits are donated to the Fiver Children’s Foundation. Considering its geographic range and core values, Fiver Children’s Foundation felt like a perfect fit with our values. Camp Fiver is a 129-acre refuge secluded in the woodlands of Poolville, NY. Every summer, the camp welcomes hundreds of children from underserved communities throughout New York City and Central New York to spend 2-4 weeks in a character building program. Camp Fiver offers your typical summer camp activities - swimming, boating, hiking, horseback riding - and at the same time campers develop skills through programs such as public speaking, health, community building, and environmental education. Fiver’s Summer Camp program is just one part of the Fiver Children’s Foundation’s 10-year commitment to its attendees. The Foundation provides year round youth development through school programing and job training, serving approximately 500 children and their families each year. Most of the children attending Camp Fiver hail from communities in NYC, yet the Camp also draws in youths from other school districts as well, including those that are nearby Kriemhild Apart from wanting to support such a successful foundation that shares our values, Kriemhild has a personal connection to the Fiver Children’s Foundation as well. Bruce and Nancy Rivington, co-owners of Kriemhild Dairy Farms and operators of Red Gate Farm (our Meadow Butter supplier), have a Camp Fiver alumni in their family. From age 10, Bruce and Nancy’s son Jamie Rivington attended Camp Fiver. “I think that that's really good for all the kids that go because it gives you a different perspective from what you’re used to seeing where you are,” Jamie recalls. “I think my favorite thing about the camp is that as you come back year after year, you get to see the same groups of people that you started with and you all go through everything together.” As of this publication, over $600 has been donated to Fiver Children’s Foundation through the Kriemhild Kupboard since it opened in the spring of 2016. We’re excited to continue nurturing our relationship with the Fiver Children’s Foundation, and we take pride in supporting the development of community-minded, environmentally-focused, courageous young people.

Stocking our farm store, the Kriemhild Kupboard, was an evolutionary process. There are so many great retail establishments in the surrounding area that carry equally-great local products (including our own), and we also set the goal of supporting our local farmers and food artisans. Although we wanted your shopping experience at the Kupboard to be familiar, we did not want it to feel redundant. With that vision, we set out with the intent to build on what we make at Kriemhild and see where that road would take us. So, naturally, we started with your favorite - Meadow Butter. Made with Kriemhild ButterButter may be our end-product, but for some of our wholesale customers, it’s just the beginning of their culinary creations. We often get asked by our customers if we make flavored butter, which is a fair question. Although Kriemhild doesn’t, we know someone who does - and does so with our butter to boot. D’Arcy Butters is a food business just a skip and hop over in Hudson, NY who mixes our Meadow Butter with locally sourced herbs and spices to make unique flavored butters. And flavored butter is not the only food where our butter acts as the main ingredient. Black and Bolyard, food crafters in Brooklyn, NY cook and caramelize our Meadow Butter, and then they infuse, season, and whip the final product to create a butter with intense, deep flavors that can be used in place of plain butter in almost any dish. We admire these fellow food crafters for their creativity and commitment to wholesome, flavorful and nutrient dense food. Carrying their products in the Kriemhild Kupboard felt like a natural extension of our company values, with the additional positive of introducing our customers to different flavors and methods of applying butter to their meals. Better with ButterWhen you step into the Kupboard, it may appear at first glance that the selection of food we carry is incidental. Yet, if you look closely enough, you’ll find that the food collection is carefully curated to complement our Meadow Butter. For instance, Mosher Farm’s popcorn -- better with butter; Johnston’s Honey Bee Farm Honey -- make your own flavored butter; Eggs -- because if you’re still cooking your eggs in some sort of oil then you’re being severely deprived; even Fojo Coffee, which may seem a like an odd one out, but add a dab of unsalted butter and you just turned your cup of joe into an energy drink! Keep it Crème FraîcheDon’t worry, we didn’t forgot about your favorite crème fraîche. Many of the non-dairy foods we sell pair perfectly with our cultured cream. With some Mizrahi Manor Granola and Maple Syrup, crème fraîche can act as a perfect base for a parfait. We carry a wide variety of spice and cheesecake mixes from Halladay’s Harvest Barn for those who want to dip (pun definitely intended) their toes into the world of crème fraîche, or those seasoned crème consumers who want to whip up a quick dish. Grab a bag of Fruit of the Fungi dried Mushrooms and Flour City Pasta and you have yourself a fantastic creamy pasta entree. Dairy GoodThere is an obvious theme that strikes most people when they visit the Kupboard: we stock many forms of dairy. Since we’re only able to produce Meadow Butter and Creme Fraiche at this time, we feel having the Kriemhild's Kupboard is a good opportunity to feature other regional dairy processors whose work complements our own, and perhaps share some attention with a few of the lesser-known producers or there. For instance, Jones Family Farms Gelato is a dessert gaining traction in the area, and we can certainly understand why. They offer a great selection of unique flavors and even more interesting, they make their Gelato from the milk of multiple animals. You can choose whether to have flavors made in traditional cow milk gelato, or branch out into goat or sheep milk. There’s even Sorbetto for those who may enjoy a dairy-free treat. You may have seen that we carry Grassy Cow cheese curds and East Hill Farms cheese because, first of all, they’re really good tasting cheeses, and secondly, we identify with them as a fellow small, grass-based dairy producers. If you've stopped by a farmers market lately, you may learn that we connected with Trimona Organic Yogurt through our wonderful co-packer, Sunrise Family Farms. This bulgarian yogurt is made with the milk from several farms across Chenango County. We loved the its taste, its imaginative flavors, and its cultural roots. We felt it would be similar to a yogurt we would have liked to make. For those attending the Hamilton Farmer’s Market, Cazenovia Farmer’s Market, and the Pleasantville Farmer’s Market, we will be carrying Trimona Yogurt for sale alongside our own Meadow Butter and crème fraîche. We’re hoping you’ll find that, with its selection of responsibly-made and regionally-sourced food, the Kupboard will be a place of culinary introduction or inspiration for those who drop in. If you stop to shop, you’ll definitely find something a little different than you would at a larger grocer, and a bit more unique than every other farm store. We searched far and wide to make sure that would be the case.

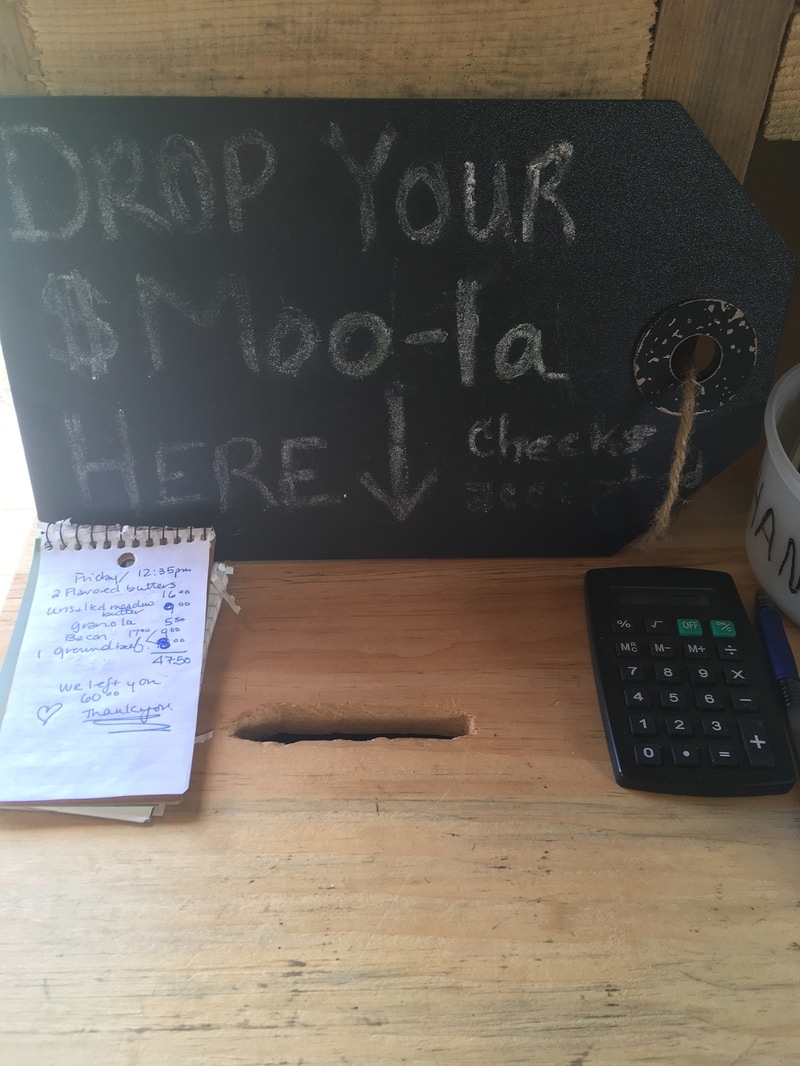

We reap what we sow.Because of your (our customers’) patronage and word-of-mouth advertising over the years, Kriemhild is honored to have over 150 wholesale partners across New York State, New Jersey, Pennsylvania, Connecticut, and Massachusetts (each of which replenish numerous super markets, restaurants, bakeries, and independant grocers), as well as many more retailers we personally deliver to. Because of you, we have proudly grown into a regional dairy presence. And while we’re certainly thrilled to watch our wholesale business grow, we never want to lose sight of our stomping -- or rather, our “churning” grounds. While our seasonal Meadow Butter and our Crème Fraîche are carried in many stores throughout the northeast United States, and are also available for purchase online, there’s still something to be said for the level of familiarity between producer and consumer that comes from the intimacy of in-person-transactions. It’s one of the reasons why we, as well as many of you, enjoy attending farmer’s markets. We get to see you in person and experience the joy you have for the food we make, to answer your questions, and to hear your feedback firsthand. Our farm store The Kriemhild Kupboard began as a natural extension of the familiarity that we embrace at farmers’ markets. There’s a sign along route 12B, not far from Red Gate Farm, our sole Meadow Butter supplier, that marks the site of our future creamery; the sign optimistically says “Kriemhild Creamery”. Until creamery construction begins, we use the site as inventory storage for future Meadow Butter and Crème Fraîche shipments, and also as our administrative headquarters. Yet, many of you had suggested that it would be optimal to be able to buy your butter directly from Kriemhild HQ. So, with timber harvested from Red Gate Farm, and hard work from Amish carpenter Roman Troyer, the Kriemhild Kupboard was built last spring. Now, you can pick up not only our Meadow Butter and Crème Fraîche as you pass by, but there’s also a variety of dairy delights including but not limited to: cheese curds from the Grassy Cow, Trimona grass fed bulgarian yogurt, Black and Bolyard brown butter and, our team favorite, Jones Family Farm gelato. Indeed, the Kupboard has given us a great outlet not only to market our food, but the food from our favorite farmers and food artisans as well. If you visit the Kupboard, you’ll notice that the store is completely unstaffed. We choose to run the store on the honor system, so customers are responsible for tallying their own total and making their own change (don’t worry, we provided a calculator and a note pad). We believe that you trust us to make your food, and so we’ll trust you to pay for it. Of course, we’re sure you recognize the risk in leaving money and product unattended, and then advertise that both are there. But so far the experience has been positive, and so our mutual trust continues. We are starting to realize that the Kupboard doesn’t just offer convenience for locals, but a sense of community as well. It seems our efforts to be transparent and accountable are being echoed by our customers. For instance, Kupboard visitors are not required or instructed to write down what products they buy, but they often do us the courtesy. We’ve had weeks when the income from the Kupboard has been short, only to receive a check in the mail a few days later to square up an I.O.U left in the cash box. People are not just paying for their food, but going out of their way to perpetuate the honor system. More consumers want to know how their food is made, to the point where they want to consume their food in the place where it is made. You want to eat bagels in bakeries, drink beer at breweries, and have lunch at butcher shops. You want to know who’s handling your food. And we get it. It’s not just about ensuring the quality of the food (although that is a significant part). It’s about feeling like a part of a community and offering your contribution to support good foodcraft. We look forward to the day when you can stop by to enjoy a bite at the Kupboard and gaze upon our new and fully-functional creamery, reveling in the knowledge that the people who are making your food possess integrity and share your values. And while you sit there taking it all in and savoring the flavors, it hits you that as a customer you had a part in building an honor system that’s much, much more than just a simple farm store.

Honorably Yours, -- Ellen Fagan When Being Yellow Bellied is a Good Thing…We love the first day of butter making. There’s nothing like churning the first cream of the season into a 1200 pound mountain of smooth, lightly salted, very yellow butter. As we take a ceremonial first taste, we have to ask: why is spring butter so magical? Milk is a complex mixture of fat, proteins, carbohydrates, minerals, vitamins and other miscellaneous constituents dispersed in water. Yet, the amount of these components vary based on the cow’s diet, the breed of cow, and a cow’s stage of lactation. Being a seasonal, grass-fed dairy is reflected in how our butter tastes and also how it changes over the course of the grazing season. Spring butter has an unmistakable yellow glow. This color is affected by the increased amount of fresh grass in the cows’ diet during the spring as they start grazing. Fresh forage is bountiful in carotenoids, classes of mainly yellow, orange, or red fat-soluble pigments, which then manifests in our high fat butter. When ingested by a cow, one carotenoid in particular, beta-carotene, is converted to vitamin A. This results in a butter with a higher vitamin A content in the spring. Winter butter is produced primarily when the cows are on stored feed such as hay and hay ferment, so it is paler in comparison. If you don’t notice a huge change of color in our butter, it’s ok. Many of the cows that produce our butter are mixes of breeds that naturally produce milk with a higher carotene content regardless of the season (i.e. Jerseys and Guernseys). Also, very often the cows at Red Gate Farm are grazing fresh forage well into November, and don’t stop milking until December. So, there is a small window in which we are creating “winter butter” from a mix of fresh forage and stored forage. Because of all of these variables, the color shift over the grazing season is subtle, gradual and not at all linear. More than just the color, the texture of Meadow Butter changes over the season as well. Spring butter is perfectly spreadable, if not slightly leaky, while winter butter can be firmer, even appear to be somewhat brittle. This change reflects the saturation of milk fat in the butter. The presence of longer-chain saturated fatty acids increases the hardness of butter. Milk with a high proportion of unsaturated fatty acid content tends to create softer, runnier products. During their outdoor grazing period, our cows’ milk is composed of lower saturated fatty acids and higher unsaturated fatty acid concentrations. During the winter, when the herd is fed stored forage, the reverse is true and our cream contains more saturated fats and less unsaturated fats. Saturated fat molecules are more uniform, and they form crystal structures more readily than unsaturated fats. These fat crystals yield a firmer product with a higher melting point. Many bakers consider the firmness of winter butter better for baking, finding that it makes it easier to work into a dough and bakes into perfect flaky pastries and crusts. One final variable that affects Meadow Butter is you. Since, our butter can be frozen without compromising its taste or texture, if you choose to squirrel some away for the winter, then you can enjoy spring butter year-round. In fact, at Kriemhild we store our butter reserves in a commercial freezer between packing and farmer’s markets or wholesale shipments. This storability is also why we attempt to reserve enough to bridge the winter off-season, though (as our regular customers know) demand has historically outpaced our rate of butter-bank deposits -- which is another reason why we “run out” each winter. Although we at Kriemhild Dairy rejoice the arrival of our spring butter, we celebrate the seasonal variation in dairy. With its cycles, subtleties, ebbs, and flows, we embrace all the nuance that seasonal dairy brings -- yes, even the off-season. After all, absence makes the heart grow fonder (and hungrier), and experiencing seasonality garners true appreciation for the natural rhythms of our food system.

Why no Butter?You may have recently found yourself asking this when at a local Farmer’s Market or a Kriemhild Dairy retail partner. We’re willing to bet this question has come to mind in a few of you because we’ve certainly been fielding a good many inquiries about our current Meadow Butter “shortage.” <--finger quotes implied Our quick answer when asked is simply that our sole supplier for our Meadow Butter source milk, Red Gate Farm, is a seasonal dairy farm. Unlike farms that implement rotational breeding, Red Gate chooses to breed their cows together to follow nature’s rhythm of pasture grass growth. This choice means that the moms-to-be have been dried-off (a.k.a. not-milking during the final months of pregnancy) since December, and by extension, we do not yet have milk to make your favorite butter. Although this short explanation gets the general point across, we would like to dig deeper on what commitment to being a seasonal farm really means: a holistic farm management choice that is far more subtle and intricate than just the result of a perceived butter-famine in the dead of every winter. Milk, like all other food, has a season; not that many of us realize that nowadays. Before the introduction of grain feeding practices, farmers were keen to match a cow’s peak milk production to pasture quantity and quality. This meant breeding in the fall, and calving around March and April. This schedule closely mimics nature, as most wild grazing animals give birth in the spring when there is high food availability as they nurse their growing offspring. A seasonal dairy is different from a year-round dairy in that all the cows are on the same breeding and birthing schedule. This results in the whole herd going dry for the same two month period in the winter to save up energy for birthing in the spring. On a year-round dairy, each cow still dries off for two months, but since the breeding and calving periods are staggered, different groups of cows go dry at separate times of the year, giving the illusion of seasonless food production. Many year-round dairy farms find that grain or corn silage (a fermented feed made from corn stalks) work best in order to meet the cows’ high nutrient requirements during the winter milking. High quality stored pasture feeds like hay and hay ferment (haylage) can also meet winter production nutrition needs. Seasonal management lessens the reliance on grain, corn products, and stored forages. The Rivington family have been managing their herd seasonally since 2005, only a few years after starting Red Gate Farm in Hamilton, NY. They chose to manage the farm seasonally for a few reasons. Firstly, because of their commitment to grass-fed farm management, organizing their herd’s reproductive cycles around the the grazing season made practical sense; their cows are able graze on fresh, nutritions pasture when their nutrient requirements are the highest (during lactation), and then can maintain their body condition on stored forages throughout the winter when they are not milking and therefore have lower nutritional needs. Another logistic factor that complemented seasonal production was their selection of an open-air milking parlor design. Red Gate Farm’s milking parlor is bright and breezy in the summer, providing ample ventilation (and vitamin D) for both bovines & humans during milking times. By extension, given the climate of Upstate NY, this design doesn’t necessarily lend itself to the most comfortable temperatures for humans or cows during the winter. Drying off the herd for two of the colder months of the year, again, works with nature and limits this issue. In addition to providing their cows with the best nutrition, eliminating their need for grain, and compensating for their limited infrastructure, the final major factor supporting seasonally dairying is a human one: it offers the Rivington family a break from the twice-a-day (and sometimes thrice-a-day) milking for two months. With their daily farm work hours reduced from time-and-a-half down to part-time, the Rivington family can sleep full nights, have weekends off, reflect on the season, plan for the future, and most importantly recharge before going back at it for another 10 months straight.

In spite of these benefits, do not be deceived! Seasonal dairying is not all sunshine and blowing bubbles in your milk. The trade off for the two-month break during the winter is two epicly intense periods of breeding and calving. In order to dry off the whole herd at the same time, more the 300 cows must breed, conceive, and calve on a tight schedule. These two narrow windows of time leave very little room for mistakes, and only raise the stakes for this family farm. In order to increase the chances of having the herd bred within the same 60 day time span, all the cows must be at the pinnacle of health; wellness begets fertility. Nine months later, calving season consumes the daily and nightly, activities as the increasing number of calves need to be tagged, moved, and fed. This frantic pace can reach the extreme of one calf being born every hour. Although the breeding and calving periods are, shall we say intense, seasonal farming allows the Rivingtons to keep the pregnant cows’ and newborn calves’ wellbeing at the forefront of their focus and attention. Since Meadow Butter stores well in the freezer with no effects to its quality or nutrition, we intend to supply it to you throughout the winter as we grow our production and when we bring on more dairy farmers as Kriemhild partners. But even then, our butter, like a meadow, will still be produced seasonally, and remains a seasonal product. So, you see, the “shortage” (finger quotes again) isn’t really a shortage, but a natural ebb between swells of abundance. We feel that highlighting this connection between the foods we love and the seasons of nature is essential to understanding what it means to be well nourished. We’re having a Cow! It’s Calving Season at Red Gate Farm…Spring is a sacred season on any farm. Produce farms can finally put their seeds in the warm ground, chicks are hatching from eggs, and livestock graze on lush spring pastures. At Red Gate Farm, spring arrives with a hundreds of babies mooing. Located down the road from Kriemhild Dairy in Hamilton, NY, Red Gate Farm is our sole milk supplier for our seasonal Meadow Butter. It is the second-largest grazing dairy in New York State and is owned and run by the Rivington family who practice holistic grazing management for over more than 1,500 acres of land. The typical dairy farm produces milk year-round, meaning that calves are born throughout the year on a staggered schedule. Being a seasonal dairy, Red Gate Farm goes about breeding and parturition differently. All the cows at Red Gate are bred in the same span of time and therefore give birth in one short period at the beginning of spring. As you can imagine, it is the busiest time of the year on the farm. The dairy farm lingo for a cow that has given birth is “fresh”. At Red Gate Farm over 350 cows freshen over a two month period. At this time, the farm transitions to a maternity ward. It is the birth of the calves that begins the cows’ natural lactation which will peak through the bountiful grazing season and continue until December. But for as busy and hectic as it is, the season specifically set aside for calving is also reverent. Its suddenness and newness is the ultimate acknowledgement of the fertility and abundance of new life that comes with the spring season. As we all look forward to another season of fresh grass-fed Meadow Butter, we’re also just as excited to receive the newest additions to the herd. About 140 of the calves born this spring will be the future milking cows of Red Gate Farm, known by the term “heifers”, which is a pretty good gig as cow-jobs go. So far, more 100 calves have been born this season. As the calf barn fills up with brand new bouncing baby bovines, we’re gearing up to introduce you to them. On Saturday, April 29th, Red Gate Farm is hosting Calving Day. Whether or not you have visited the farm before, Calving Day will be a great time to make a trip. It will be a special event highlighting the natural cycle and processes that surround seasonal grass-fed dairy farming. We encourage anyone who wants to know more about where their food comes from to join us at the farm to celebrate the start of the season. Until then, we’ll be keeping you abreast with our Calving Day COW-ntdown (we couldn’t help ourselves). As our Calving Day event approaches, we’ll be counting-down the days and adding-up the number calves we’ve welcomed to the farm. Stay tuned on social media & here on our website for the running total of fresh baby calves! |

As the Butter Churns

Author: Ellen Fagan and Victoria PeilaCategories

All

Archives

November 2019

|

Where our HEart is

|

FOLLOW US |

what our customers are saying"Thank you! Even though I'm 5 hours away...I can't live without you. Got my shipment today.

#kriemhildbutterlove" -- Jennifer in Mystic, Connecticut |

Copyright 2020 © Kriemhild Dairy Farms, LLC

RSS Feed

RSS Feed